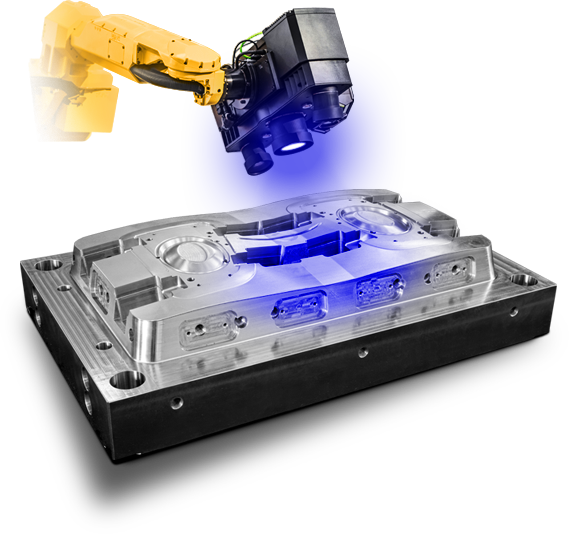

Investing heavliy on state of the art equipment and software allows us to bring you the best consultancy services available backed up by decades of experience.

Using the latest CREO 3D design technology, We take a problem and deliver cost effective solutions, endless capabilities, precise and entuituve.

From one off small bespoke batches to simple 2D profiles through to full 3D CNC machined tools, We have a wide expertise accross many tooling applications.

Our work is always produced to the highest specification, using precise measuring equipment and software, we’re confindent we can offer the best.

Using the latest 3D modelling Solutions

We use Creo, a leading 3D CAD software that enables us to maximize productivity and quickly explore innovative design options, creating a solutions that best meets your requirements.